Intellidyne Business Systems©

Innovative Information Science and Technology Services for today.

Innovative Information Science and Technology Services for today.

Our expertise in delivering outstanding software development and maintenance productivity helps you build unparalleled quality into your software projects at any stage in the development process. Our unwavering commitment to customer satisfaction and quality solutions fosters lasting business relationships with our clients, vendors, employees and partners.

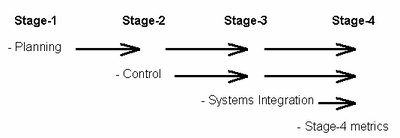

The ideal program utilizes both techniques, and focuses on the most expedient method to enhance the understanding and implementation of any particular concept. At the core of the Stage I, and Stage 2 analyses are the qualitative relationships between the variables. This highlights the principles involved in the maintenance process and it cannot be quantitative (except from an holistic viewpoint), simply because the data is not yet available. The modeling technique is therefore best suited to make major progress in the early stages.

The Stage 3 and 4 analyses focus on quantitative metrics to a greater extent, and this is the area where advanced researchers can have a field day. The drawback of this type of research is the fact that the majority of manufacturing organizations reside in stage-2 maturity, and therefore cannot benefit directly from this research.

The logical sequence of the maintenance strategy process consists of three phases, namely:

The Stage 3 and 4 analyses focus on quantitative metrics to a greater extent, and this is the area where advanced researchers can have a field day. The drawback of this type of research is the fact that the majority of manufacturing organizations reside in stage-2 maturity, and therefore cannot benefit directly from this research.

The logical sequence of the maintenance strategy process consists of three phases, namely:

There are some major (generic) elements that are common to all strategy designs, because they are essentially linked to maintenance maturity indexing. These elements will affect your maintenance performance, irrespective of whichever strategy you pursue. They are listed here below, corresponding to the maturity stage where they start to have maximum relevance:

Planning, the key to stage-1 progress, does not stop after stage-1, but must be maintained and enhanced right through to stage-4. If you do not improve your planning you cannot leave stage-1. That's it, bottom-line.

Proper control can only be achieved in stage 2, by definition. This happens when:

All relevant variables operational in the specific maintenance environment have been identified,

The relationships between the variables are clear to all, and

Action has been taken to optimize the desired outputs, by focusing on the inputs to each process.

Control can be measured qualitatively to the extent that there are no more surprises.

Congruency, or systems integration, is the major key to stage-3 progress. (It is not the only key either) It is impossible to achieve effective (permanent) congruency, if good planning and control systems have not been established, and this cooperation must extend beyond the boundaries of the maintenance function. A CMMS is not an instant solution to the congruency dilemma.

The metrics of stage-4 is difficult to define due to the fact that it cannot be researched to any significant extent. Few organizations have reached this stage, and those that did are not always keen to share their strategies. Trust, teamwork and cooperation seem to be some of its attributes, but the foundation for these aspects has to be laid long before an organization reaches stage-4. If this has not been done you will not reach stage-4.

A very interesting fact is that these four maturity stages, and their associated keys are just as valid in the marketing, finance and operations environments, as they are in maintenance.

A formal maintenance strategy can be developed in either of two ways: These are the "Policy" technique and the "Modeling" technique.

Planning, the key to stage-1 progress, does not stop after stage-1, but must be maintained and enhanced right through to stage-4. If you do not improve your planning you cannot leave stage-1. That's it, bottom-line.

Proper control can only be achieved in stage 2, by definition. This happens when:

All relevant variables operational in the specific maintenance environment have been identified,

The relationships between the variables are clear to all, and

Action has been taken to optimize the desired outputs, by focusing on the inputs to each process.

Control can be measured qualitatively to the extent that there are no more surprises.

Congruency, or systems integration, is the major key to stage-3 progress. (It is not the only key either) It is impossible to achieve effective (permanent) congruency, if good planning and control systems have not been established, and this cooperation must extend beyond the boundaries of the maintenance function. A CMMS is not an instant solution to the congruency dilemma.

The metrics of stage-4 is difficult to define due to the fact that it cannot be researched to any significant extent. Few organizations have reached this stage, and those that did are not always keen to share their strategies. Trust, teamwork and cooperation seem to be some of its attributes, but the foundation for these aspects has to be laid long before an organization reaches stage-4. If this has not been done you will not reach stage-4.

A very interesting fact is that these four maturity stages, and their associated keys are just as valid in the marketing, finance and operations environments, as they are in maintenance.

A formal maintenance strategy can be developed in either of two ways: These are the "Policy" technique and the "Modeling" technique.

A model is usually represented by a one-page cryptic document. It is an attempt to capture in condensed, schematic format, all the relevant variables pertaining to a section of, or to the entire maintenance environment, and is essentially holistic by its very nature.

This method enables us to accommodate the complexity of the maintenance process with relative ease. It is properly a strategy analysis technique, and thus resorts under the preparation phase, but is just as effective in the strategy design phase.

It has the following major advantages:

At one glance, it provides an overview of the process

Critical variables are not overlooked inadvertently

It calls for relationships to be defined.

A pre-requisite for successful modeling is the ability to handle the abstract concepts inherent in the maintenance process, and to have an appreciation of basic mathematics in order to be able to understand the relationships between the variables. This ability is not very common and relates to educational standards. The cryptic nature of the model, which is its seemingly major disadvantage, is in fact one of its best features: It is difficult for outsiders to understand, and therefore it can provide a truly competitive edge, which cannot be copied.

The modeling process starts of with a series of questions. These need to be the right questions! If you ask the wrong questions, the probability of getting the right answers are close to zero.

An example of a wrong type of question to ask is:

"Why are our maintenance costs so high?"

The traditional response to this question is to dig up a few high cost items from the last 3 month's expense reports, and to offer a plausible explanation for each. That usually settles the issue (until the next month's variance reports).

A better option is to apply Pareto analysis to the high-cost contributors, and to find the root cause of the problems.

The best option however, would be to view the maintenance environment as a process, and then to ask the following questions:

This method enables us to accommodate the complexity of the maintenance process with relative ease. It is properly a strategy analysis technique, and thus resorts under the preparation phase, but is just as effective in the strategy design phase.

It has the following major advantages:

At one glance, it provides an overview of the process

Critical variables are not overlooked inadvertently

It calls for relationships to be defined.

A pre-requisite for successful modeling is the ability to handle the abstract concepts inherent in the maintenance process, and to have an appreciation of basic mathematics in order to be able to understand the relationships between the variables. This ability is not very common and relates to educational standards. The cryptic nature of the model, which is its seemingly major disadvantage, is in fact one of its best features: It is difficult for outsiders to understand, and therefore it can provide a truly competitive edge, which cannot be copied.

The modeling process starts of with a series of questions. These need to be the right questions! If you ask the wrong questions, the probability of getting the right answers are close to zero.

An example of a wrong type of question to ask is:

"Why are our maintenance costs so high?"

The traditional response to this question is to dig up a few high cost items from the last 3 month's expense reports, and to offer a plausible explanation for each. That usually settles the issue (until the next month's variance reports).

A better option is to apply Pareto analysis to the high-cost contributors, and to find the root cause of the problems.

The best option however, would be to view the maintenance environment as a process, and then to ask the following questions:

|

What are the variables that affect the cost of our maintenance process? |

|

Can these variables be grouped - to make more sense? |

|

What are the relationships between them and the desired output? |

|

Which of them are dependant variables, and which are independent? |

|

What are the inter-relationships between the inputs, and what is the optimum level of each? |

Restrict yourself to using a singe page for this whole exercise in order to retain the holistic focus. Now it is a simple matter to identify, and to take action, on those first basic independent variables that affect maintenance costs. Such as - tools; spares; skills; attitudes; lubrication; and plant availability for maintenance. When these aspects have been addressed and optimized, the total maintenance cost will reduce. Further analysis of the model will reveal other, more advanced variables that can be addressed to reduce maintenance costs, but it makes no sense to address them unless the basics are in place first, and you can demonstrate high performance on the basics.

It is therefore of crucial importance that the relevance of a model must be defined with relation to maintenance maturity. Different levels of maintenance maturity require different decision criteria and different solution sets.

It is therefore of crucial importance that the relevance of a model must be defined with relation to maintenance maturity. Different levels of maintenance maturity require different decision criteria and different solution sets.

|

Preparation |

|

Design |

|

Implementation |

Maintenance strategy design depends on preparation, and implementation depends on design, in turn. Inadequate preparation will result in a poor design, which will result in an unworkable implementation of your maintenance strategy.

The preparation phase is seldom the subject of a separate focus. It main tenets are Research, Audit, Analysis, Marketing and Training. It is not an easy phase, because it presupposes most of the strategy parameters. This anomaly is resolved by performing one or more iterations of the entire process, especially in the case where an organization designs a maintenance strategy from zero base. Several of the aspects of the preparation phase are continuous, and not a once- off exercise. If this phase is neglected, the Implementation Phase just becomes that more difficult, if not impossible.

The preparation phase is seldom the subject of a separate focus. It main tenets are Research, Audit, Analysis, Marketing and Training. It is not an easy phase, because it presupposes most of the strategy parameters. This anomaly is resolved by performing one or more iterations of the entire process, especially in the case where an organization designs a maintenance strategy from zero base. Several of the aspects of the preparation phase are continuous, and not a once- off exercise. If this phase is neglected, the Implementation Phase just becomes that more difficult, if not impossible.

What are the principles that are operational in the maintenance environment?

The complexity of the maintenance environment, and the general lack of business rules and data discipline dictates that a staged, congruent set of solutions, rather than a single option must be pursued in order to effect permanent progress.

These solutions are not primarily technical in nature, nor are they particularly difficult to understand. Technical brilliance is seldom associated with good management abilities, and even less seldom with a strategic focus or a pro-active culture.

Certain solutions can only be introduced into the maintenance process at a specific stage of process maturity, with any guarantee of success. Others, like improved planning, always pay off.

It is not possible to "jump" into World-Class maintenance from no-where. Consistent and steady progress is typically achieved through staged "growth". Instant growth has not yet been invented.

Ownership will be achieved if the organization and its people design and construct their own policies and models required for transformation to World-Class performance levels. This will result in a true competitive edge, which cannot be bought out.

The extraordinary large time-constants in the maintenance environment compound the problem. Decisions made years ago, (by someone else) may only have their effect sometime in the future. If these decisions were not enacted through a visible strategy there is no way to be forewarned.

Some major policies that affect the maintenance process are beyond the direct control of the typical maintenance function.

Hundreds of small decisions are made everyday on the shop floor that impact on the day-to-day effectiveness of the maintenance process. People that use a limited, and wrong frame of reference, in most cases, make these decisions.

The complexity of the maintenance environment, and the general lack of business rules and data discipline dictates that a staged, congruent set of solutions, rather than a single option must be pursued in order to effect permanent progress.

These solutions are not primarily technical in nature, nor are they particularly difficult to understand. Technical brilliance is seldom associated with good management abilities, and even less seldom with a strategic focus or a pro-active culture.

Certain solutions can only be introduced into the maintenance process at a specific stage of process maturity, with any guarantee of success. Others, like improved planning, always pay off.

It is not possible to "jump" into World-Class maintenance from no-where. Consistent and steady progress is typically achieved through staged "growth". Instant growth has not yet been invented.

Ownership will be achieved if the organization and its people design and construct their own policies and models required for transformation to World-Class performance levels. This will result in a true competitive edge, which cannot be bought out.

The extraordinary large time-constants in the maintenance environment compound the problem. Decisions made years ago, (by someone else) may only have their effect sometime in the future. If these decisions were not enacted through a visible strategy there is no way to be forewarned.

Some major policies that affect the maintenance process are beyond the direct control of the typical maintenance function.

Hundreds of small decisions are made everyday on the shop floor that impact on the day-to-day effectiveness of the maintenance process. People that use a limited, and wrong frame of reference, in most cases, make these decisions.

|

Preparation |

|

Strategy Design |

|

Research |

|

Audit |

|

Analysis |

|

Marketing |

|

Training |

|

Context |

|

Demographics |

|

Infrastructure |

|

Logistics |

|

Operating Environment |

|

Maintenance History |

|

Resource Listing |

|

Objectives |

|

Performance Indicators |

|

Micro Strategies |

|

Database |

|

Continuous Improvement |

|

Strategy Implementation |

|

Restructuring and Stratification |

|

Guidelines |

|

Modeling |

|

Custodians |

|

Policies & Procedures |

|

Principles |

|

Maxims |

|

Action Plans |

|

Iteration #; and Definitions |

Copyright © 2000-2008 by "Intellidyne Business Systems" · All Rights reserved · E-Mail: webmaster@ibsicom.com

EMPLOYERS

RECRUITERS

RESUME SERVICE

LOGINS